Do you have questions or would you like a detailed quote?

Click above for a larger image and a technical diagram

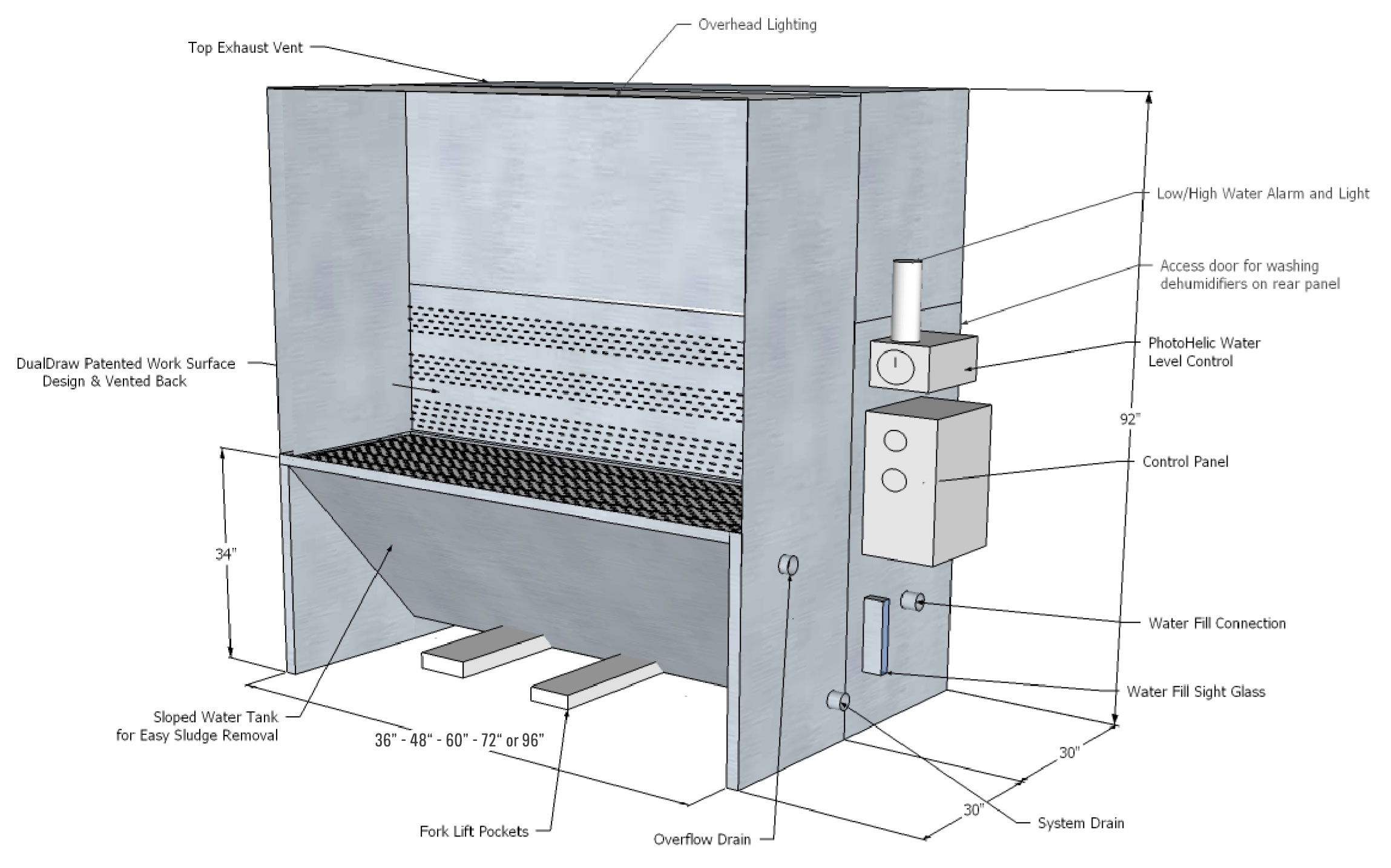

Wet Downdraft Booths

Wet downdraft booths are designed for the safe and efficient capture/collection of flammable or explosive metal dusts generated from aluminum, magnesium, titanium or similar metals. They use water as their primary filtration method to capture the combustible dust and particulate, and come standard with a perforated downdraft work surface, (2) fixed sides, the vented backstop, and an overhead top with a light.

This style of enclosure is typically used by customers who have standard part sizes that do not vary, and is useful for processes that require extra visibility, such as an inspection process, where the overhead light is used. Each unit follows NFPA 484 guidelines and is the only wet downdraft design in the market tested for particle capture efficiency. If you’re looking for a wet downdraft booth to facilitate the capture and collection of flammable or explosive metal dusts, look no further.

All of the wet downdraft booths we offer are covered by a multi-year warranty and are built to last. With 100% heavy-duty 304 stainless steel construction, this solution will work for you upon start-up and for many years beyond. We hope to have the opportunity to work with you and provide solutions to your project requirements.

Want more information?

We would love the opportunity to evaluate your specific needs and provide you with the most accurate and detailed information possible. Please continue scrolling for detailed product information, or click the ‘Contact Us’ button to request more information or speak with us directly.

Why Downdraft Booths Are Useful Tools

STANDARD WET DOWNDRAFT BOOTH SIZES AND CONFIGURATIONS

| MODEL | WORK SURFACE | NOMINAL CFM | TABLE CAPACITY | APPROXIMATE SIZE (D x W x H) | ||

|---|---|---|---|---|---|---|

| TB1826-WET | 18″ x 26″ | 1600 | <1000 lbs. | 42″ x 34″ x 81″ | ||

| TB3036-WET | 30″ x 36″ | 3000 | 1000 lbs. | 54″ x 48″ x 92″ | ||

| TB3048-WET | 30″ x 48″ | 4000 | 1000 lbs. | 54″ x 60″ x 92″ | ||

| TB3060-WET | 30″ x 60″ | 5000 | 1000 lbs. | 54″ x 72″ x 92″ | ||

| TB3072-WET | 30″ x 72″ | 6000 | 1000 lbs. | 54″ x 84″ x 92″ | ||

| TB3096-WET | 30″ x 96″ | 8000 | 1500 lbs. | 54″ x 108″ x 92″ | ||

| CUSTOM COLOR OPTIONS AVAILABLE. CALL US TODAY AT (800)784-5816 FOR DETAILS | ||||||

Get a Quote Today

No pressure. Let us know what materials and/or particulate you’ll be working with, and we will give you detailed information that is easy to understand, along with competitive pricing and our highest level of customer service.