Do you have questions or would you like a detailed quote?

Self-Cleaning Downdraft Tables

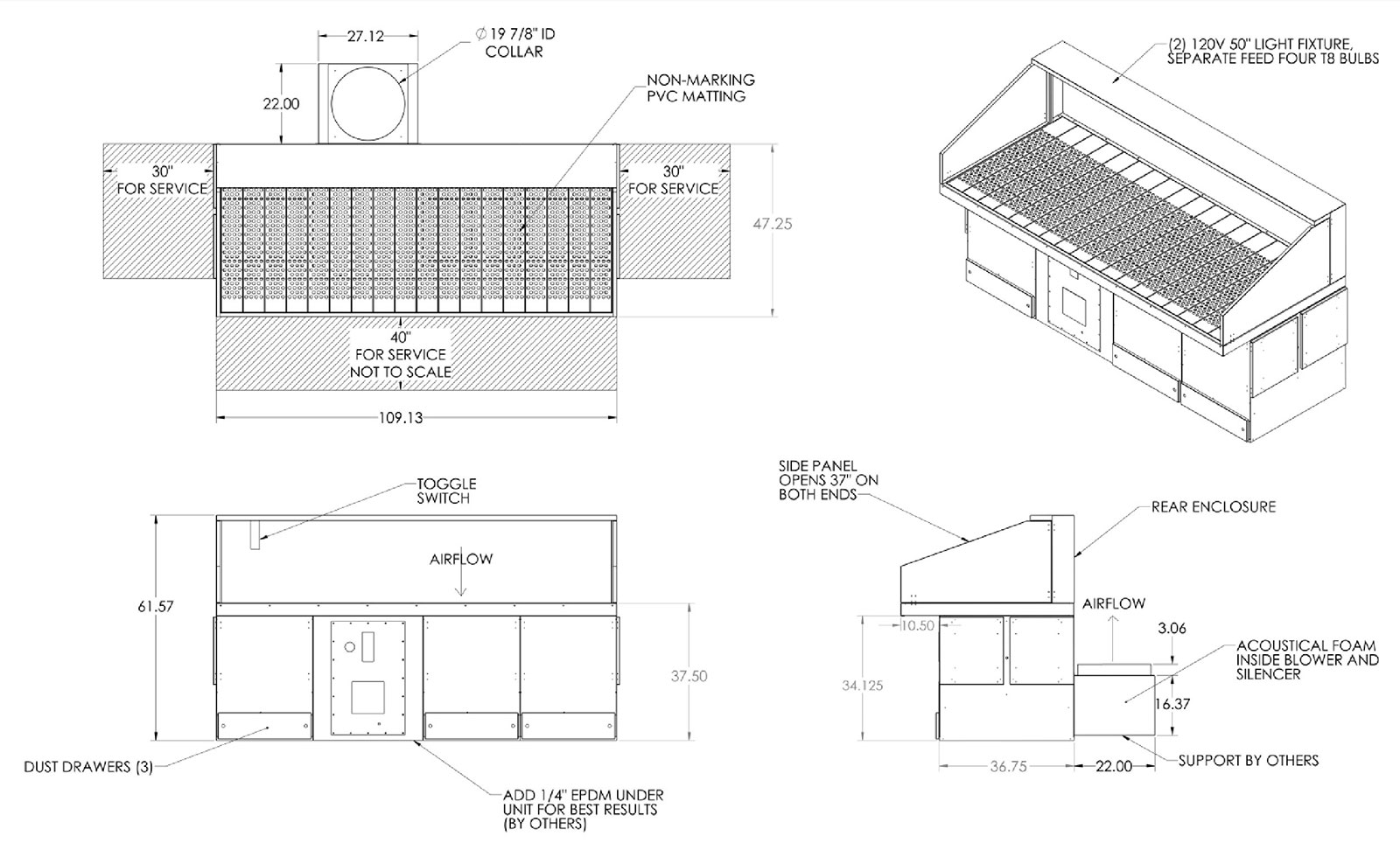

Self-cleaning downdraft tables are designed to minimize maintenance and reduce replacement filter costs. They provide efficient, cost-effective control of dust, smoke, fume, and gas/vapor contaminants generated from a variety of manufacturing and process applications. Typically used for control of moderate to heavy concentrations of dry contaminants, this series of tables can be used for grinding, polishing, and dry buffing.

The self-cleaning systems can be either manual or automatically controlled to minimize maintenance and reduce replacement filter costs, and aid in compliance with local OSHA regulations by drawing contaminants away from the operator’s breathing zone.

One of the many benefits of the APB self-cleaning downdraft system is its adaptability. This system is available in two configurations – with or without a fixed back and hinged sidewalls. The flat-top downdraft configuration (without back/sidewalls) is great for larger parts that can be accessed from all sides of the table, and the configuration with back/sidewalls (which can also be removed as necessary) is great for containing sparks and debris that are generated by welding/finishing processes. Contact us for more information!

Want more information?

We would love the opportunity to evaluate your specific needs and provide you with the most accurate and detailed information possible. Please continue scrolling for detailed product information, or click the ‘Contact Us’ button to request more information or speak with us directly.

- Airflows range from 2500 to 5050 CFM depending on tabletop size and motor horsepower

- 99% filter efficiency at 0.5 micron particulate size

- Heavy duty galvanized grating table top and rear wall with hinged side wing panels are standard

- Direct drive backward inclined airfoil non-overloading fan

- Manual push-button reverse pulse filter cleaning system

- Mini-helic filter change-out gauge

- High capacity dust drawer

- 11, 12 and 16 gauge heavy duty metal construction

- Kelly Green industrial textured powder coat finish

- Manual motor starter

- Optional timer controls are available such as a timer and Smart Pulse with downtime cleaning

- Water pan or metal mesh for added protection against sparks due to grinding

- Filter options to include spun bond, hydro-oleophobic, and high-efficiency NANO fiber cartridge media

- If smoke is present an additional HEPA cabinet can be provided

- Tabletop surfaces such as fiberglass grating and steel bar grating

- Slotted back draft is an for welding applications

- blower motor upgrades available

- Multiple color options available (contact us for details)

The Unit in Action

Did you know…

The terms ‘downdraft table’ and ‘downdraft bench’ are synonymous with one another and are often used interchangeably. If your project requirements specify a table or a bench, either one will work for your application.

STANDARD SELF-CLEANING DOWNDRAFT TABLE SIZES

| MODEL | WORK SURFACE | MOTOR HP | TABLE CAPACITY | APPROXIMATE SIZE (D x W x H) | ||

|---|---|---|---|---|---|---|

| APB4250 | 42″ x 50″ | 3 / 5 | 1100 lbs. | 43″ x 50.4″ x 62″ | ||

| APB4276 | 42″ x 76″ | 5 / 7.5 | 1650 lbs. | 43″ X 76.75″ X 62″ | ||

| APB48108 | 48″ x 108″ | 7.5 / 10 | 2365 lbs. | 48″ X 109″ X 62″ | ||

| AVAILABLE IN EITHER FLAT-TOP CONFIGURATIONS OR WITH FIXED BACK WALL AND HINGED SIDEWALLS | ||||||

All APB self-cleaning downdraft table models include the following features:

Nominal CFM ranges from 2500 to 5050 depending on application, table model and blower motor used.

Get a Quote Today

No pressure. Let us know what materials and/or particulate you’ll be working with, and we will give you detailed information that is easy to understand, along with competitive pricing and our highest level of customer service.