Do you have questions or would you like a detailed quote?

Click above for a larger image and technical diagram

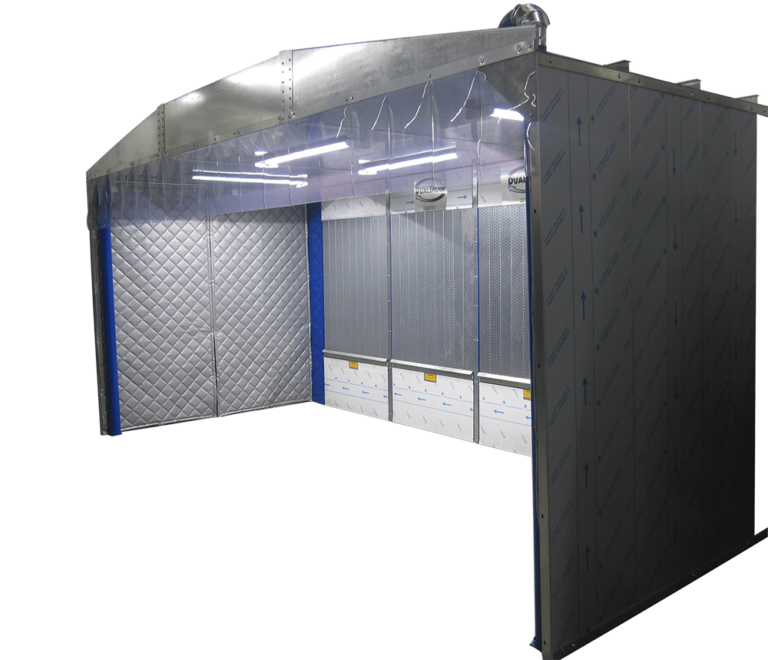

Walk-In Dust Booths

Walk-In Dust Booths are used by a wide variety of customers who need to capture dust and/or fumes, but also require operational flexibility. Some instances include work processes that need to be performed unencumbered, multi-step processes, or customers working on large parts. These customers often use Walk-In Clean Air Stations to address their industrial dust or hazardous fume issues. For example – finishing processes on large jet engine assemblies or performing multi-step weighing processes of powders and bulk solids.

Walk-in Dust Booths, when equipped with the optional “Regain Air” systems, capitalize on the multiplied ventilation effect of “pushing” clean air out across the front of the booth as the blower “pulls” contaminated air into the filters – which creates a walk-in booth (also known as Environmental Control Booth) that is a dust capture workhorse.

Want more information?

We would love the opportunity to evaluate your specific needs and provide you with the most accurate and detailed information possible. Please continue scrolling for detailed product information, or click the ‘Contact Us’ button to request more information or speak with us directly.

- Built-in lighting provides a bright, well-lit working environment

- Pre-packaged as a complete unit that requires no duct work

- Corrosion resistant aluminum side panels and roof panels (on many units)

- Easy access dust drawers make dust disposal safe and easy

- Regain air ducts are adjustable and direct clean air across booth side or top (depends on booth style & design)

- Cartridge filters used are 99+% efficient

- All electric typically included; junction boxes are pre-wired

- Low noise level

- Sound curtains available for additional noise reduction

- T.E.F.C. direct drive motors

- 5000 – 50000 CFM packages

- Pre-packaged for easy installation

- High Capture Velocity: “Regain Air” provides for high capture velocities. When ordered, the automatic self-cleaning system assures that the booth maintains its outstanding performance.

- High Performance Blowers: Energy conserving low speed, high flow blowers have airfoil blades for high fan efficiency as well as low noise and reduced electrical consumption.

- Efficient & Effective Filtration: Filtration media (cylindrical cartridge or panel filter media) is recommended as application and budgetary constraints dictate.

- Enhanced Work Environment: Our walk in booths are designed to provide optimal conditions for industrial operations where dust and/or noise are a problem.

- Freedom of Movement: The high capture velocity provided means that workers are free to work anywhere within the booth as production requires.

- Visibility: Effective source capture of smoke, fumes, and dust provides consistent visibility within the work area of the booth.

- Safety & Productivity: Walk in environmental control booths are designed to effectively capture air borne contaminants. Worker productivity is typically increased while providing for the health and safety of the booth workers.

The Unit in Action

Get a Quote Today

No pressure. Let us know what materials and/or particulate you’ll be working with, and we will give you detailed information that is easy to understand, along with competitive pricing and our highest level of customer service.