Do you have questions or would you like a detailed quote?

Click above for a larger image and technical diagrams

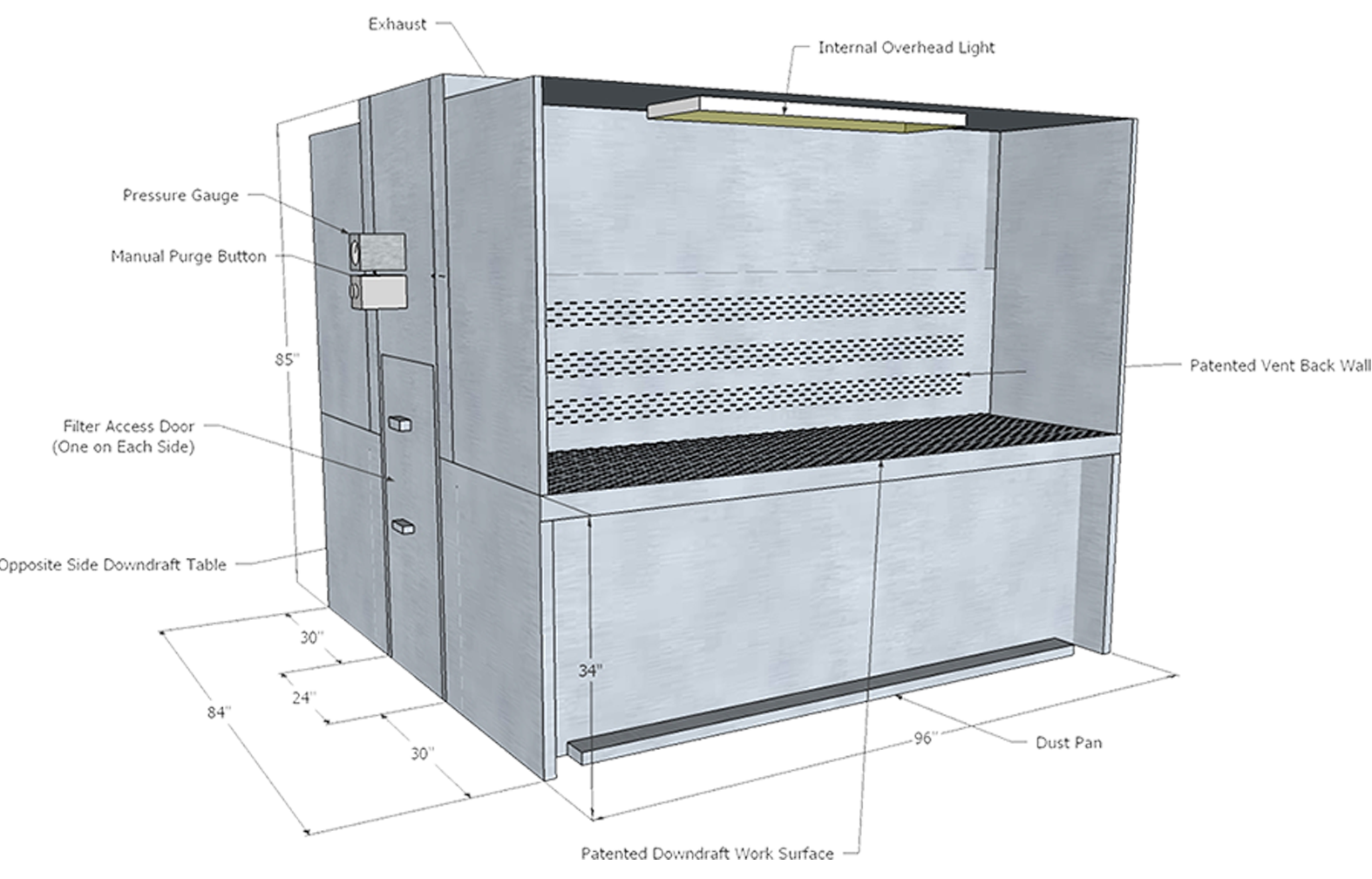

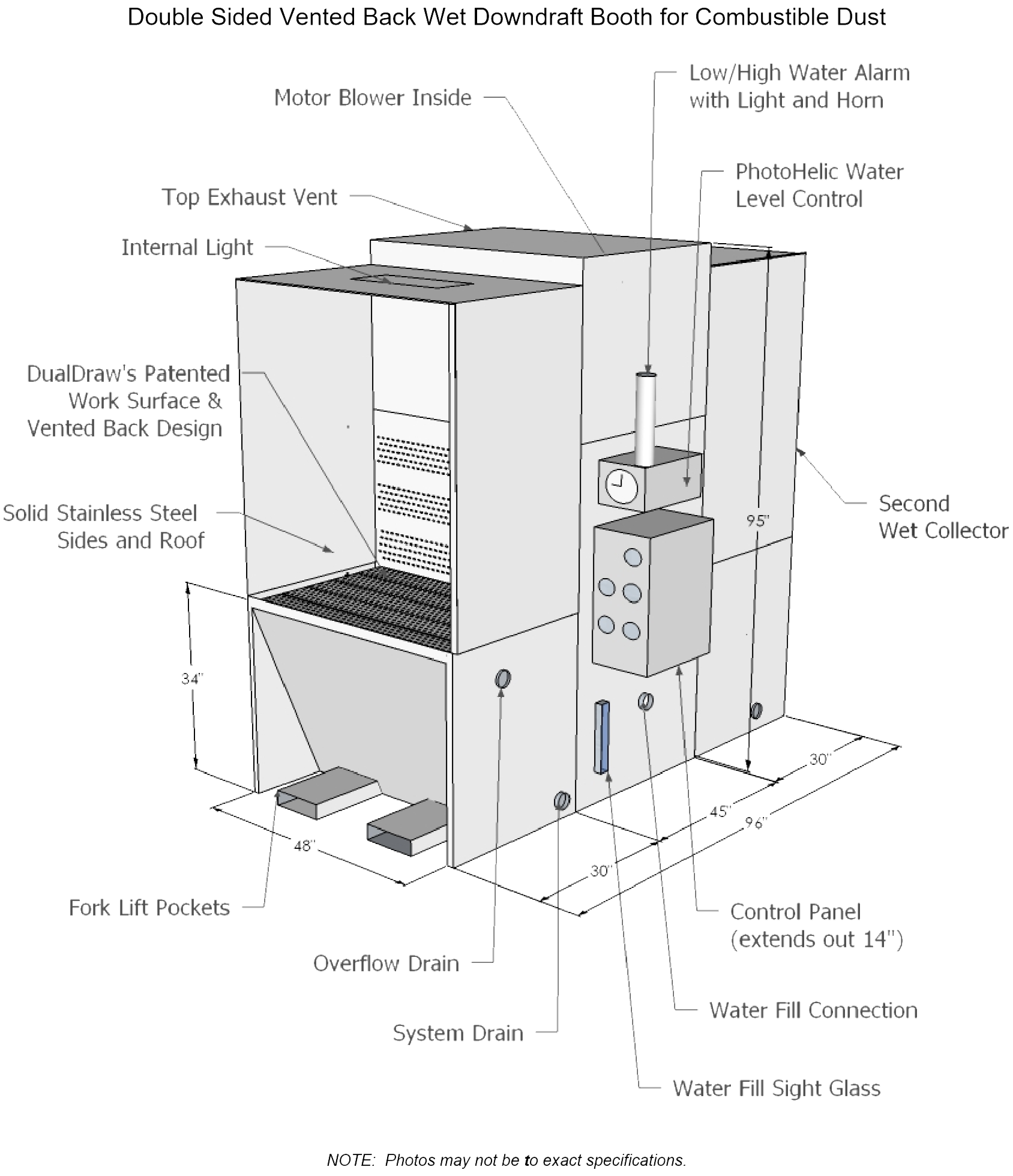

Double-Sided Downdraft Systems

Double-sided downdraft tables and booths offer significant cost and space savings by offering two identical opposing work surfaces in a single downdraft system. This becomes increasingly beneficial if your project requires performing multiple grinding, deburring, welding, or other operations that create hazardous dust/fumes/debris, and there are space limitations in your production facility. Not only do these systems offer the potential to expedite workflow, they also offer the benefit of sharing one filtration unit – making the double-sided downdraft tables and booths more efficient and cost-effective to operate and maintain.

Double-sided downdraft systems are available in both wet and dry configurations and can be customized to suit your production requirements.

Want more information?

We would love the opportunity to evaluate your specific needs and provide you with the most accurate and detailed information possible. Please continue scrolling for detailed product information, or click the ‘Contact Us’ button to request more information or speak with us directly.

- 12 gauge stainless steel construction for all metal surfaces that are in contact with water; non-wetted surface construction to be 14 gauge stainless steel

- Motor and blower are of a direct drive plug fan design; TEFC motor with backward inclined impeller wheel design; non-sparking

- Impeller to have at least a double water reversal design and have a minimum of 3” to 4” of pressure loss

- Sludge collection tub to be angled and have clear access for removal of sludge

- Automatic water level control (5 probe design) supplied on all units unless otherwise requested by the customer

- An after filter/mist eliminator combination is included to capture any fugitive mist

- The blower outlet chamber is lined with a minimum of ½” closed cell poly foam

- Heavy duty grating is provided with options for a variety of soft cover materials for part protection

- Each work surface grate is removable for easy sludge removal and maintenance

- Hinged and removable side wing panels (included with all units)

- Rubber soft top or fiberglass heavy duty grating (optional)

- Full combination magnetic motor starters (included with all units)

- 3/4 HP vent fan for off line positive air flow (optional)

- Fluorescent overhead lighting (available as a standalone kit)

The Unit in Action

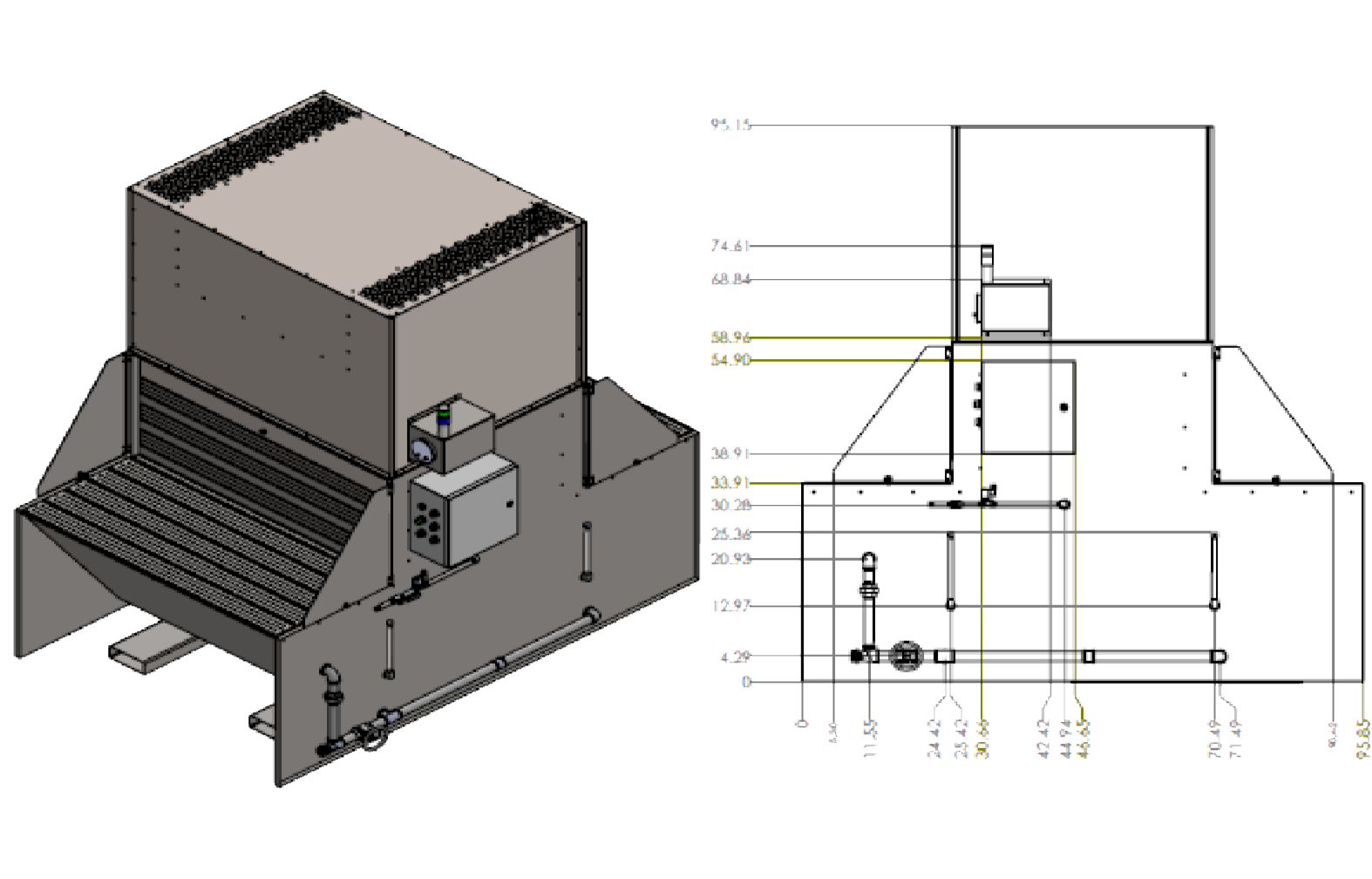

Double-sided wet downdraft table front and side view

Did you know…

The terms ‘downdraft table’ and ‘downdraft bench’ are synonymous with one another and are often used interchangeably. If your project requirements specify a table or a bench, either one will work for your application.

DOUBLE-SIDED DOWNDRAFT TABLE SPECIFICATIONS

| MODEL | WORK SURFACE | TABLE CAPACITY (PER SIDE) | ||||

|---|---|---|---|---|---|---|

| BG3036-DBL-WC or BG3036-DBL-SC | 30″ x 36″ | 500 lbs. | ||||

| BG3048-DBL-WC or BG3048-DBL-SC | 30″ x 48″ | 500-750 lbs. | ||||

| BG3060-DBL-WC or BG3060-DBL-SC | 30″ x 60″ | 1000 lbs. | ||||

| BG3072-DBL-WC or BG3072-DBL-SC | 30″ x 72″ | 1000 lbs. | ||||

| BG3096-DBL-WC or BG3096-DBL-SC | 30″ x 96″ | 1500 lbs. | ||||

| ALL SYSTEMS ARE AVAILABLE IN BOTH WC=WET COLLECTOR (COMBUSTIBLE METAL) AND SC=SELF-CLEANING (NON-COMBUSTIBLE MATERIAL) CONFIGURATIONS. PLEASE CALL US AT (800)784-5816 FOR MORE INFORMATION. | ||||||

DOUBLE-SIDED DOWNDRAFT BOOTH SPECIFICATIONS

| MODEL | WORK SURFACE | TABLE CAPACITY (PER SIDE) | ||||

|---|---|---|---|---|---|---|

| TB3036-DBL-WC or TB3036-DBL-SC | 30″ x 36″ | 500 lbs. | ||||

| TB3048-DBL-WC or TB3048-DBL-SC | 30″ x 48″ | 500-750 lbs. | ||||

| TB3060-DBL-WC or TB3060-DBL-SC | 30″ x 60″ | 1000 lbs. | ||||

| TB3072-DBL-WC or TB3072-DBL-SC | 30″ x 72″ | 1000 lbs. | ||||

| TB3096-DBL-WC or TB3096-DBL-SC | 30″ x 96″ | 1500 lbs. | ||||

| ALL SYSTEMS ARE AVAILABLE IN BOTH WC=WET COLLECTOR (COMBUSTIBLE METAL) AND SC=SELF-CLEANING (NON-COMBUSTIBLE MATERIAL) CONFIGURATIONS. PLEASE CALL US AT (800)784-5816 FOR MORE INFORMATION. | ||||||

Get a Quote Today

No pressure. Let us know what materials and/or particulate you’ll be working with, and we will give you detailed information that is easy to understand, along with competitive pricing and our highest level of customer service.