Do you have questions or would you like a detailed quote?

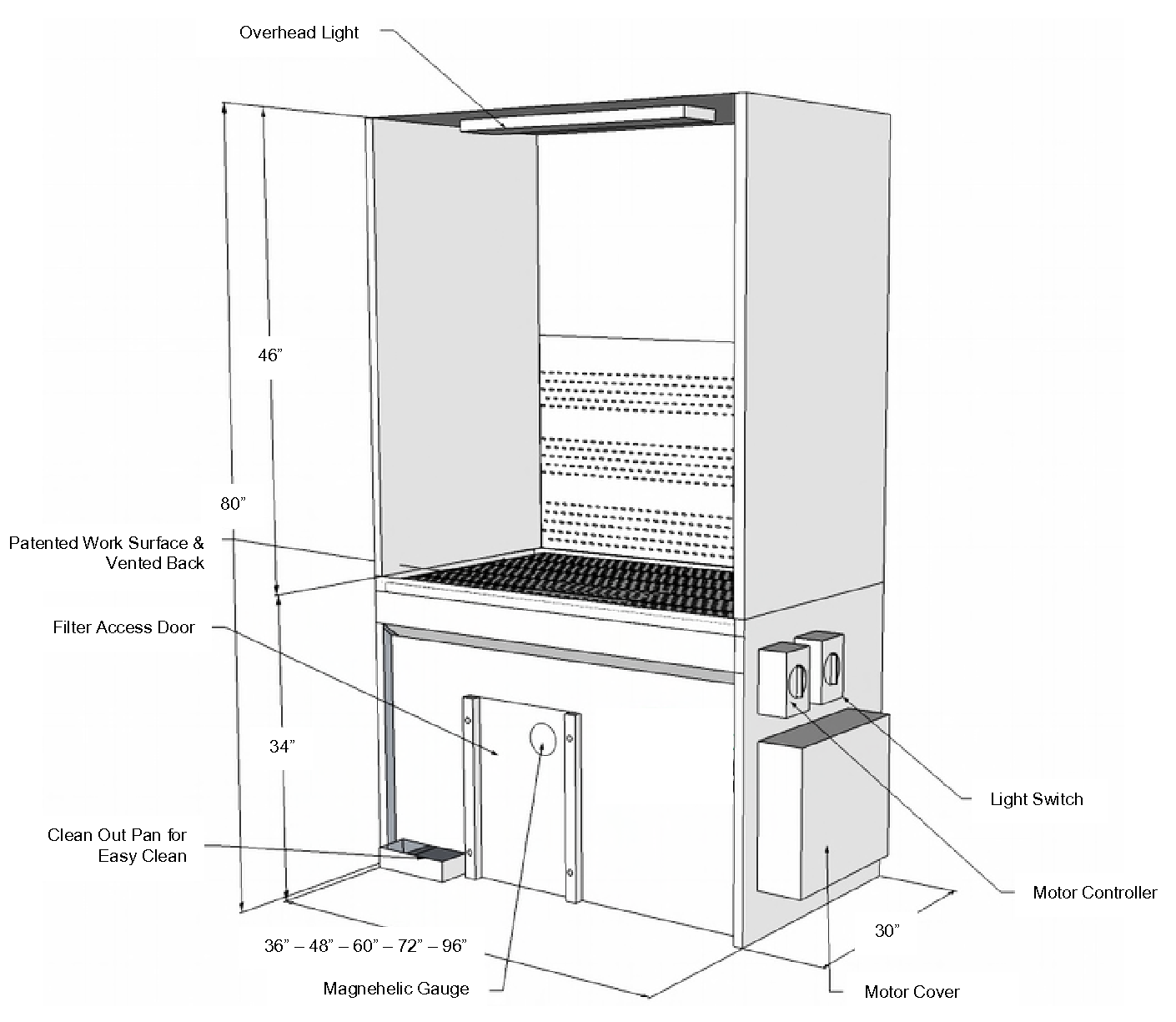

“Dual Draw” Style Downdraft Booths

Downdraft booths allow maximum containment of dust and fumes through its 5-sided enclosure that surrounds the downdraft work surface and vented back. The enclosed workspace of the booth design significantly decreases the risk of cross drafts and directs airflow in a highly efficient manner. For these reasons, this style of equipment is an optimal choice for some of the most hazardous applications.

In certain applications, keeping the maximum containment of dust and fumes in mind, it is advantageous to select a downdraft booth with a lower FPM (feet per minute) because the air will be moving through the filter media at a slower speed. One example would be capturing fumes and/or odors exclusively. If you’re capturing particulate, you will most likely want a booth with a higher FPM (higher velocity) to ensure the largest amount of particulate is captured. Our engineering team will walk you through selecting the appropriate blower motor and filtration setup for your particular application. Please contact us at (800) 784-5816 for more details.

Want more information?

We would love the opportunity to evaluate your specific needs and provide you with the most accurate and detailed information possible. Please continue scrolling for detailed product information, or click the ‘Contact Us’ button to request more information or speak with us directly.

Why Dry Downdraft Booths Are Useful Tools

- Average Face Velocity = 150 – 400 FPM(dependent upon blower/motor combination)

- 2000 CFM – 5000 CFM (nominal) blowers

- 14 and 16 Gauge uni-body construction

- Direct drive blower motor

- Large work surface for a range of applications

- Full back, side and ceiling panels

- Removable clean-out tray in filter housing

- Completely self-contained; no outside ducting necessary

- Helps meet OSHA requirement 1910:1000 for industrial air quality

- Maximum containment of dust and fumes

- Custom is standard

- HEPA filtration; 99.97% efficient @ 0.3 microns

- Caster wheel system for easy movement

- Rubber table mats for non-scratch working surface

- Removable dust pan in main body of unit for easy clean-out

- Multiple color options available (contact us for details)

The Unit in Action

STANDARD DOWNDRAFT BOOTH SIZES (CUSTOM CONFIGURATIONS & SIZES WELCOME)

| MODEL | WORK SURFACE | NOMINAL CFM | TABLE CAPACITY | APPROXIMATE SIZE (D x W x H) | ||

|---|---|---|---|---|---|---|

| TB3036 | 30″ x 36″ | 2000 | 500 lbs. | 54″ x 38″ x 80″ | ||

| TB3048 | 30″ x 48″ | 2500 | 500 – 750 lbs. | 54″ x 50″ x 80″ | ||

| TB3060 | 30″ x 60″ | 2500 | 1000 lbs. | 54″ x 62″ x 80″ | ||

| TB3060-A | 30″ x 60″ | 4000 | 1000 lbs. | 54″ x 80″ x 80″ | ||

| TB3072-A | 30″ x 72″ | 4500 | 1000 lbs. | 54″ x 78″ x 80″ | ||

| TB3096-A | 30″ x 96″ | 5000 | 1500 lbs. | 54″ x 98″ x 80″ | ||

| ANY ‘DUAL DRAW’ STYLE BOOTH CAN BE BUILT IN A ‘WET’ CONFIGURATION FOR COMBUSTIBLE METAL DUST 35″, 40″, 45″, & 50″ DEPTHS ALSO AVAILABLE UPON REQUEST PLEASE CONTACT US FOR MORE INFORMATION ON CUSTOM SIZES AND CONFIGURATIONS |

||||||

| MODELS WITH THE “-A” SUFFIX INDICATE A DUAL-MOTOR CONFIGURATION | ||||||

Designed With the Disabled in Mind

DualDraw is the first company to manufacture downdraft tables and downdraft booths that have been designed with the disabled in mind. They are wheelchair accessible for ADA (Americans with Disabilities Act) requirements. All employees – including the physically challenged – should be able to work in a safe and comfortable environment designed to meet their needs. All downdraft tables and downdraft booths have plenty of table top room for extra tools and accessories. Electrical outlets are provided and are within easy reach.

Get a Quote Today

No pressure. Let us know what materials and/or particulate you’ll be working with, and we will give you detailed information that is easy to understand, along with competitive pricing and our highest level of customer service.